No.1 Stainless Steel Gratings Manufacturing Company in Chennai

Steel Man Laser is the no.1 Stainless Steel Gratings Manufacturing Company in Chennai in various sizes and specifications. The raw materials used for manufacturing of gratings shall confirmed to AISI 304/ AISI316 OR 309, OR as per your requirement.

Manufacturing Process : The gratings are assembled and welded as per specifications. For finishing purpose the gratings shall be acid washed & electro-polished to achieve the best finishing.

Steel Man Laser utilizes advanced manufacturing processes and state-of-the-art technology to produce mild steel gratings that meet industry standards and customer requirements. We emphasize precision and quality in their production methods to ensure that each grating is sturdy and reliable.

Mild steel gratings manufactured by Steel Man Laser are made from high-quality mild steel, which is known for its excellent strength-to-weight ratio. This makes the gratings suitable for applications that require both durability and ease of installation. The mild steel material used in the production process undergoes rigorous testing and quality control measures to ensure its integrity and performance.

Steel Man Laser offers a wide range of mild steel gratings with different configurations, sizes, and load-bearing capacities to suit various project requirements. The gratings are available in different types, such as flat bar gratings, serrated bar gratings, and I-bar gratings, providing options for different applications and environments.

The mild steel gratings from Steel Man Laser are designed to provide excellent traction and drainage, making them ideal for platforms, walkways, stair treads, ramps, and industrial flooring. They are also commonly used in infrastructure projects, such as bridges, highways, airports, and railway stations, where safety and reliability are of utmost importance.

What are Mild Steel Gratings

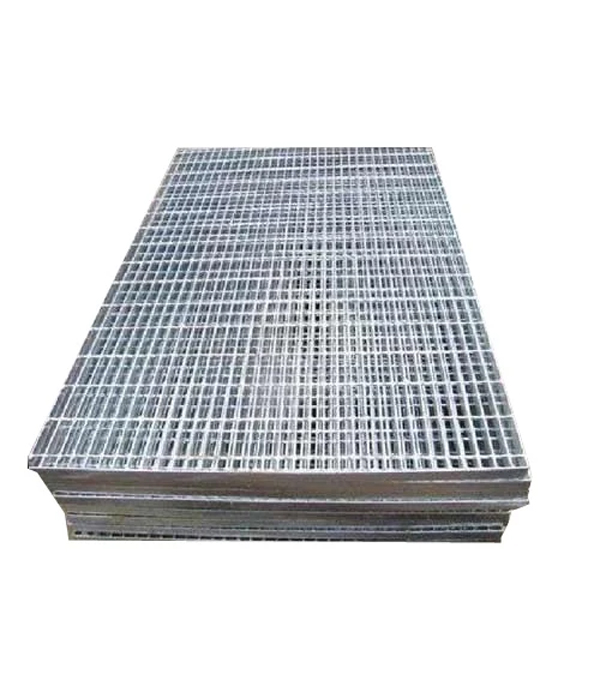

Mild Steel gratings are robust and versatile flooring solutions widely used in industrial, commercial, and public spaces. They consist of a series of parallel metal bars or beams, interconnected by perpendicular crossbars, forming a grid-like pattern. Mild Steel gratings are manufactured using mild steel, a low-carbon steel known for its strength and durability.

The primary purpose of Mild Steel gratings is to provide a stable and secure walking surface while allowing the passage of air, light, and liquids. They offer several advantages, including high load-bearing capacity, resistance to corrosion, and ease of installation. Mild Steel gratings are commonly used in various applications such as walkways, platforms, stair treads, mezzanines, ramps, drainage covers, and catwalks.

The design and construction of Mild Steel gratings make them suitable for environments that require effective drainage, ventilation, and slip resistance. The open grid structure allows debris, water, and other substances to pass through, preventing the accumulation of moisture and ensuring a safe walking surface.

Mild Steel gratings are available in different sizes, patterns, and finishes to meet specific project requirements. The choice of grating type depends on factors such as load capacity, span, deflection, and aesthetic preferences. Common types of Mild Steel gratings include welded gratings, press-locked gratings, and swage-locked gratings.

Types of Mild Steel Gratings manufactured by Steel Man Laser located in Chennai

Welded Gratings

Welded gratings are manufactured by welding the bearing bars and crossbars together at their intersections. This type of grating offers excellent strength and durability. It is suitable for heavy-duty applications and areas with high footfall and heavy loads.

Press-Locked Gratings

Press-locked gratings are constructed by interlocking the flat bars and crossbars under high pressure without the use of welding. This results in a rigid and visually appealing grating. Press-locked gratings are ideal for architectural and decorative applications where aesthetics are important.

Swage-Locked Gratings

Swage-locked gratings are produced by mechanically locking the crossbars to the bearing bars using a swaging process. This creates a strong and secure connection. Swage-locked gratings are known for their high load-bearing capacity and resistance to deflection. They are commonly used in industrial settings and areas with heavy machinery.

Grating Panels

Grating panels are pre-fabricated sections of gratings that come in standard sizes. These panels simplify the installation process and allow for quick assembly. Grating panels are available in various designs, such as serrated surfaces for enhanced slip resistance, making them suitable for a wide range of applications.

Customized Gratings

Apart from the standard types, MS gratings can be customized to meet specific project requirements. Customization options include varying bar spacings, different bar and crossbar sizes, and special finishes. This allows for tailoring the gratings to fit unique applications, ensuring optimal performance and functionality.

Key Features of Mild Steel Gratings

Strength and Durability

Our Mild Steel Gratings are crafted using superior quality mild steel, known for its strength and durability. These gratings can withstand heavy loads and are suitable for high-traffic areas.

Corrosion Resistance

We understand the importance of longevity, especially in challenging environments. That’s why our Mild Steel Gratings are coated with a corrosion-resistant finish, providing excellent protection against rust and corrosion.

Easy Installation and Maintenance

Our Mild Steel Gratings are designed for easy installation, saving you time and effort during the setup process. Additionally, they require minimal maintenance, making them a cost-effective choice for your flooring needs.

Versatile Applications

Whether it’s industrial plants, manufacturing facilities, commercial buildings, or public areas, our Mild Steel Gratings are versatile and suitable for a wide range of applications. They provide secure footing, enhance safety, and improve overall accessibility.

Customization Options

We understand that every project has unique requirements. That’s why we offer customization options for our Mild Steel Gratings, including different sizes, mesh patterns, and finishes. Our team will work closely with you to deliver gratings that perfectly match your specifications.

Things to Consider When Selecting a Mild Steel Gratings Manufacturer

When choosing a Mild Steel Gratings manufacturer, it is essential to consider the following factors:

1. Quality and Reliability

Select a manufacturer known for producing bubble caps of exceptional quality, ensuring durability and resistance to corrosion, which leads to reliable and long-lasting performance.

2. Customization Options

Ensure that the manufacturer offers customization options to tailor the bubble caps to your specific distillation requirements, ensuring optimal performance and efficiency.

3. Industry Experience and Expertise

Look for a manufacturer with extensive experience and expertise in bubble cap production. A track record of successful projects and positive customer testimonials is a good indicator of their reliability and competence.

4. Excellent Customer Support

Choose a manufacturer that provides excellent customer support, readily addressing any inquiries, concerns, or after-sales support you may require. A responsive and helpful team is crucial for a smooth collaboration.

5. Competitive Pricing and Timely Delivery

Compare prices and delivery times among different manufacturers to select one that offers competitive pricing without compromising on quality. Ensure they can deliver the bubble caps within the agreed-upon timeframe to meet your project deadlines.

Summary

Selecting the right cable trays manufacturer in Chennai is essential for ensuring quality, reliability, and efficiency in your cable management system. Consider factors such as reputation, quality standards, customization options, pricing, and delivery when making your decision.

Related Areas:

Laser Cutting, Fibre Laser Cutting, CNC Profile Laser Cutting, Metal Laser Cutting, Cable Tray, Perforated Cable, Ladder Cable, Stainless Steel Cable, Race ways Cable, Powder Coated Cable, Wire Mesh Cable, GI Cable Tray, Hot dip Galvanized Cable, Aluminium Cable, Mild Steel Grating, Electro Forged Grating, Stainless Steel Grating, Press Lock Grating.