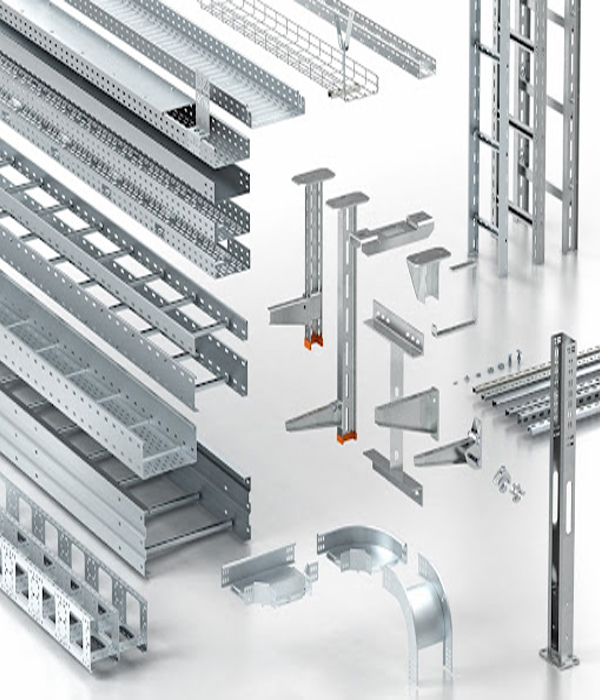

Top Perforated Cable Tray Manufacturers in Chennai – Quality & Durability Guaranteed

Steel Man Laser is the market leader in the Design and Manufacturer, Supplier, Exporter of Hot Dip GI, Pre Galvanized, Powder Coated, Electroplated, Painted Perforated Type Cable Trays, Cable Tray Systems and our setup is situated in Chennai, Tamilnadu, India

Discover the leading perforated cable tray manufacturers in Chennai, renowned for their high-quality, durable, and reliable cable management solutions. Whether you’re looking for customized designs or standard models, these manufacturers provide a wide range of options to suit your industrial and commercial needs. Explore our comprehensive list and find the perfect supplier to enhance your electrical infrastructure today.

Overview of Cable Trays

Cable trays are used to support cables for power distribution communication. They come in types such as ladder perforated, and wire mesh.

Importance of Choosing Steel Man Laser the Right Manufacturer of Cable Trays in Chennai

Selecting a reputable manufacturer ensures that you receive durable and high-quality cable trays that meet safety standards and adhere to industry regulations.

Factors to Consider When Selecting a Manufacturer

Consider the company’s reputation, product range, customer reviews, quality standards, customization options, pricing, and delivery timelines.

Top Cable Trays Manufacturers in Chennai

Let’s explore some of the top cable trays manufacturers in Chennai:

Steel Man Laser : History and Reputation

Steel Man Laser has a long-standing reputation for providing top-notch cable trays with a focus on quality and reliability.

Steel Man Laser: Range of Products and Services

Steel Man Laser offers a wide range of cable trays, accessories, and services to cater to diverse customer needs.

Steel Man Laser: Customer Reviews and Testimonials

Customers review about the exceptional service and quality products provided by Steel Man Laser, making them a popular choice in Chennai.

Perforated Cable Trays Galvanised, Electro Plated ), PAINTED ( Red Oxide, Powder Coated )

SIZES :

| Width (W) | 50mm to 1200mm |

| Height (H) | 25mm to 100mm |

| Thickness (T) | 1.6mm, 2mm, 2.5mm & 3mm |

| Length (L) | 2500mm / 3300mm |

| MOC | MS Steel, Stainless Steel, Aluminum |

| CABLE TRAY MANUFACTURING STANDARDS | |

| IS | 4759 / 2629 / 2623 |

| ASTM | 123 |

| IEC | 61537 : 2006 |

Quality Standards and Certifications

Ensuring that the cable trays meet industry standards is crucial for safety and performance.

Importance of Quality Standards

Adhering to quality standards ensures that the cable trays are reliable, durable, and safe for use.

Common Certifications in the Industry

Look for certifications such as ISO, CE, and UL to ensure that the cable trays meet stringent quality requirements.

How to Verify the Quality of Cable Trays

Inspect the material, finish, and construction of the cable trays to ensure they meet your specifications.

Types of Cable Trays ?

- Perforated Cable tray

- Ladder Cable tray

- Stainless Steel Cable Tray

- Raceway Cable Tray

- Powder Coated Cable tray

- GI wiremesh Cable Tray

- Aluminium Cable Tray

- Hot dip Galvanized Cable Tray

Customization Options and Technical Support

Customization options and technical support play a vital role in meeting unique requirements.

Understanding Customization Needs

Choose a manufacturer that offers customization options to tailor the cable trays to your specific needs.

Available Technical Support Services

Look for manufacturers that provide technical support during installation, maintenance, and troubleshooting.

Benefits of Choosing a Manufacturer with Customization Options

Customized cable trays ensure a perfect fit and seamless integration into your existing system, enhancing efficiency and aesthetics.

Pricing and Delivery

Consider the pricing and delivery options offered by the manufacturers before making a decision.

Factors Affecting Pricing

Factors such as material, size, complexity, and quantity can impact the pricing of cable trays.

Lead Times and Delivery Options

Check the lead times and delivery options to ensure that the manufacturer can meet your project deadlines.

How to Compare Prices and Choose the Best Deal

Request quotes from multiple manufacturers, compare the prices, and evaluate the overall value for money before making a decision.

Summary

Selecting the right cable trays manufacturer in Chennai is essential for ensuring quality, reliability, and efficiency in your cable management system. Consider factors such as reputation, quality standards, customization options, pricing, and delivery when making your decision.

Related Areas:

Laser Cutting, Fibre Laser Cutting, CNC Profile Laser Cutting, Metal Laser Cutting, Cable Tray, Perforated Cable, Ladder Cable, Stainless Steel Cable, Race ways Cable, Powder Coated Cable, Wire Mesh Cable, GI Cable Tray, Hot dip Galvanized Cable, Aluminium Cable, Mild Steel Grating, Electro Forged Grating, Stainless Steel Grating, Press Lock Grating.